Cardinal Scale’s CIM Series Continuous In-Motion Checkweighers keep production lines humming, reducing labor costs, and providing accurate weights of each ...

-

Products

- Products

- Baker Dough Scales

- Bariatric Scales

- Bathroom Scales

- Bench Scales

- Chair Scales

- Connectivity Solutions

- Counting Scales

- Floor Scales

- Glove Box Holders

- Hanging Scales

- Home Healthcare Scales

- In-Bed Scales

- In-Floor Dialysis Scales

- In-Motion Checkweigher

- Ingredient Scales

- Livestock Scales

- Load Cell Kits

- Load Cells

- Medical Carts

- Overhead Track Scales

- Patient Lift Scales

- Pediatric Scales

- Physician Scales

- Portable Scales

- Portion Scales

- Price Computing Scales

- Printers

- Railroad Track Scales

- Remote Displays

- Retail POS/Logistics

- Scale Diagnostic Tools

- Software

- Stadiometers

- Stretcher Scales

- Tank/Hopper Scales

- Test Weights

- Top Loading Dial Scales

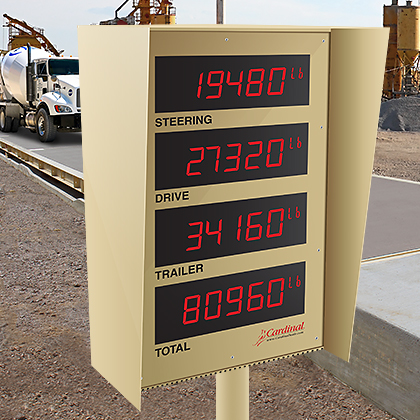

- Truck Scales

- Veterinary Scales

- Waste Receptacles

- Weight Indicators

- Wet Diaper Scales

- WheelChair Scales

-

Industries

- Aggregates

- Agriculture

- Chemical

- Clinics

- Commercial Kitchens

- Construction

- Dialysis

- Fishing

- Fitness

- Food Processing

- Highway Weigh Stations

- Home Healthcare

- Hospitals

- Laundromats

- Livestock

- Logging

- Long-Term Care

- Manufacturing

- Physician Offices

- Recycling

- Retail Point-of-Sale

- Shipping/Logistics

- Solid Waste

- Veterinary

- Company

-

Resources

-

Contacts